Instrument Performance

It is essential that the odour testing laboratory demonstrates the capability to deliver the correct dilution ratios during the odour testing. This has proved technically challenging for some odour testing laboratories, mainly due to the system design flaw. Without this capability, there is no difference between a laboratory and a random number generator.

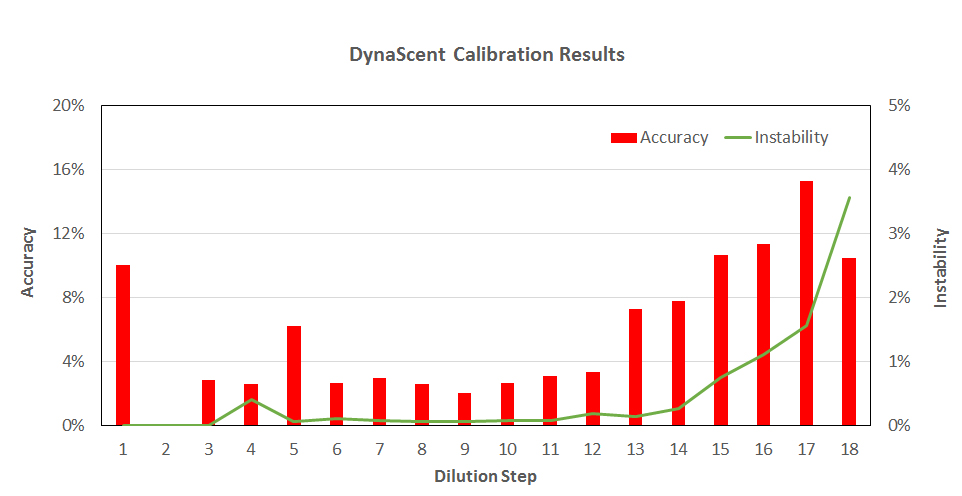

DynaScent is the only commercial olfactometer which allows users to carry out the instrumental calibration for the dilution ratios. We carry out verification for the dilution ratios after every ten panel sessions. Should the results be outside the acceptable range, we then perform calibration for the DynaScent.

DynaScent uses a series of precision metering valves to control both sample and odour free air flowrates to reach the desired dilution ratios. During the calibration, both sample and odour-free air flowrates are measured using mass flow meters and the valve openings are adjusted digitally to reach the desired dilution ratio. The metering valves driven by the corresponding servo motors have a very high resolution of ten thousandth of a turn. This fine tuning capability results in very accurate dilution ratios over the required period of time. Once the opening is confirmed, it repeats the same opening and therefore the same dilution ratio during the routine odour testing.

DynaScent calibration results in terms of instability (in green colour) and accuracy (in red colour)