Odour Concentration Measurement

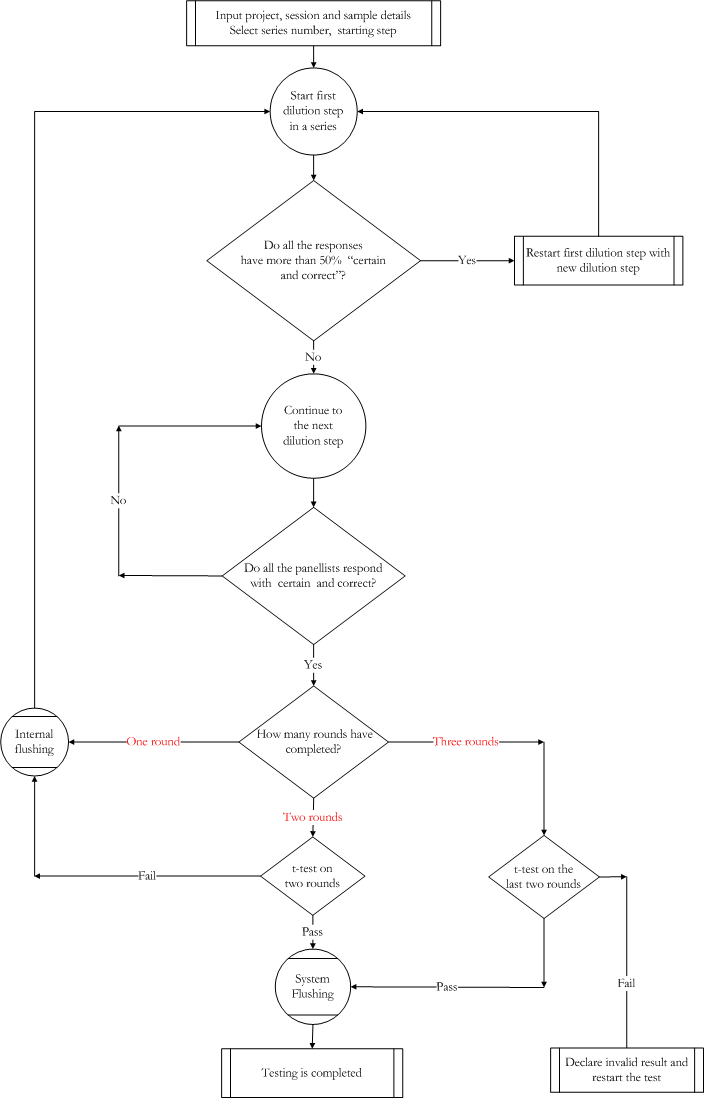

Odour concentration is the odour strength expressed in terms of the number of times the sample is diluted to reach its odour threshold. At the start of each measurement, determining the initial dilution step is of paramount importance to exclude the possibility of bias due to the operator’s preference in choosing the concentration range. The intelligent auto-range feature allows the optimum starting step to be selected based on the panellists’ responses. If more than 50% of panellists record certainty and correct (C&C) responses at the first dilution step, the current responses are discharged and the first dilution step is restarted at a new starting step. If necessary, the process is repeated. Otherwise, the next dilution step is prepared. The first series is completed when all panellists record C&C responses. A fresh starting step for the next series is then calculated according to the result of the first series. The odour testing is repeated until all panellists record C&C responses. Furthermore, a statistical analysis of the two series is performed to see if two means have a significant difference. If so, a third series will be added and the results will only be based on the two series which show no significant difference.

The odour sample is collected in a bag, which is sealed in a pressurised sample holder. The sample is mixed with odourfree air in custom designed venturi gas jets without passing through a flow measurement device. The dilution ratios are adjusted by a series of needle valves controlled by the digital precision motion controller with ±0.0001 revolution accuracy. The diluted odour sample is released via one of two sniffing cups (another cup contains only odourfree air). In succession, each member of a panel of six human observers compares the odour of the two cups without knowing which cup has the diluted odour sample. The panellists are required to select the cup from which the odour is detected and nominate the confidence level of their selection (guessing, inkling, or certainty). The olfactometer prepares the next dilution step in ascending concentration level (or descending dilution ratios). The above procedures are then repeated until all panellists detect an odour with the confident level of certainty. The odour concentration is then calculated using the panellists’ responses over a range of dilution settings. There are four operational modes:

For environmental samples, odour concentrations are used to determine the odour strength. For reference gases, odour concentrations can also be expressed as odour threshold.

The European CEN standard requires a reference gas (such as n-butanol at 60 ppm) to be presented at each panel session. The results are used to monitor the performance of the laboratory and individual panellists’ performances. In this mode, many other reference gases can also be added and their odour thresholds are determined.

Flowchart for DynaScent odour concentration testing procedure

Apply DynaScent calculation method:

- calculates the student t-test for both rounds at the end of two rounds

- accepts the result if two rounds pass

- adds 3rd round during the testing if two rounds fail

- recalculates the student t-test for every two of the three rounds

- accepts the three round result if any two pairs or all pairs pass

- accepts the two round results if one pair passes

- rejects the result if three pairs fail and claim the testing result is invalid