Instrument Calibration

In the early days, most olfactometers have used “measure and mix” technique to prepare samples for the panellists. Flow meters like rotameters and mass flow meters were inevitably used to control the different dilution ratios. When it comes to accuracy of the dilution, one would think that it is a matter of confirming the flow rates where the flow meter measures. As a matter of fact, the European measurement standard instead suggested a tracer calibration method. It is a secondary standard which can introduce much high measurement uncertainty in instrument performance. Furthermore, this calibration technique cannot even be applied to several models of olfactometers such as intermittent flow pattern or multiple booths system. Failure or refusal to provide the instrument performance result casts more doubt on the reliability of the odour measurement results.

After fully considering the technical advantages and disadvantages of its predecessor, DynaScent simplified the “measure to mix” process to “open and mix” and incorporated the “measure” in the olfactometer calibration stage. In other words, DynaScent repeatedly opens several highly accurate metering valves during the testing and confirms the dilution ratio by measuring the flow rates during calibration. DynaScent is the only olfactometer in the market which offers the user calibration feature.

This innovative design has made a significant impact on the olfactometer instrument performance.

A laboratory shall comply with both instrument and sensory quality criteria specified in the European and Australian standards to claim compliance. Unfortunately, it is difficult, if not impossible, to check the performance of some types of olfactometers. For example, the dilution ratio of the olfactometer with mixing and splitting flow arrangement could not be checked. The flow rate of the olfactometer with intermittent flow pattern cannot be measured. Although many trace gases like ammonia, hydrogen sulphide, and carbon monoxide are used to check the instrument performance, the large discrepancy between the measured and expected values have been observed. Until now, the accuracy of the dilution ratio of the olfactometer is rarely reported.

From many years of research and development, a unique technique has been developed to assess the instrument performance against instrument quality criteria. Unlike its predecessor, DynaScent uses neither splitting flow nor intermittent flow to prepare the dilution and sample presentation. Therefore, a direct mixing and presentation arrangement enables the DynaScent to apply this simple technique. Both sample flow rate and presentation flow rate are measured using two mass flow meters. The flow readings are displayed on the screen in real time. The user could easily adjust flow rates by changing the openings/settings of the valves to meet the required dilution ratio. Once this adjustment is completed, the system carries out the performance test to determine the dilution ratios for every dilution step. All the measured flow rates are saved in the database.

This olfactometer calibration technique has metrological traceability if the mass flow meters are calibrated using the primary calibration standard.

As a result of the performance testing, the measured dilution ratios are calculated for each dilution step. These ratios, not theoretical values, are used in the final measurement calculation.

The European Standard EN 13725:2003 states:

|

The quality requirements for the performance of the analytical method as a whole and of equipment used to present the sample to the assessor are the core of this standard. Compliance of the dilution equipment used by a laboratory to the instrumental quality requirements shall be tested and demonstrated regularly. The appropriate calibration frequency shall be based on the performance history of the equipment, but shall be at least once a year. Compliance testing shall involve the full dilution range of the instrument, with at least two points for each decade of dilution factor Z. For instruments with discrete dilution settings, every setting shall be tested for compliance. 6.5.5 Calibration procedure Five test results shall be collected for every dilution setting,. Between measurement for each test result the controls of the dilution instrument, if this is applicable, are set to another setting. Each test result yi,d shall consist of at least ten observations oj with a sampling frequency no less than once in every 10 s. This is relevant for the determination of instability. The lag time of the monitor, including the sampling system, shall not be more than one cycle of the sampling frequency. To obtain one test result, at least 10 observations shall be recorded. Performance quality requirements are:

|

Olfactometer instrumental performance is one of two quality requirements stated in the European and Australia standards. This part should be done before the sensory performance and should not be replaced by sensory performance.

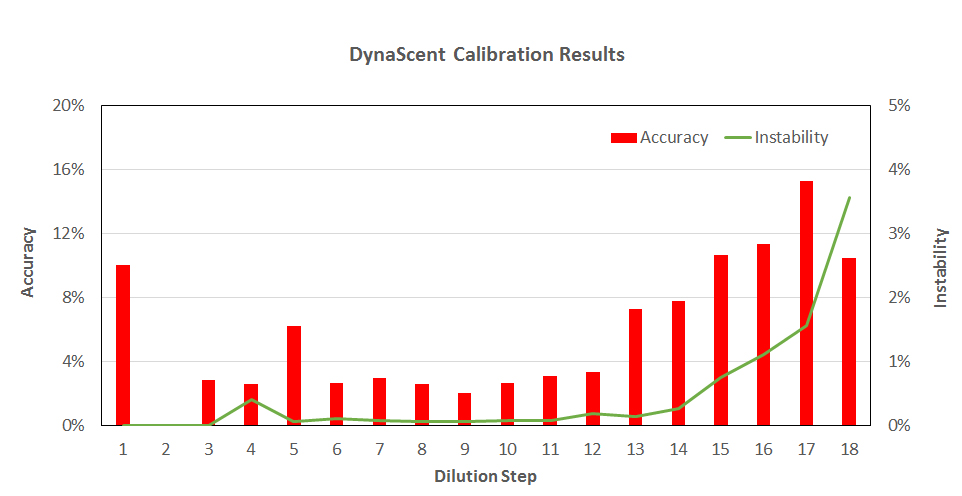

The following figure shows the instrumental calibration results. The bar represents the accuracy on the left and the curve represents the instability on the right.