Technical Specifications

System design

Gas mixing is achieved in the venturi gas jets and dilution ratios are controlled by needle valves

Control principle

An intelligent motion controller with control modules which drive micromotors to adjust the needle valves

Testing mode

Binary or triangle forced choice method in descending or ascending order for odour concentration

0 - 6 scales in random order for odour intensity

Ambient odour is presented without dilution at 20 L/min

Standard dilution range

2 - 262,000 in 18 steps with a dilution factor of 2 or 3 - 100,000 in 10 steps with a dilution factor of 3.3 (user selectable)

Instability

less than 1% for dilution ratio smaller than 2,000

less than 2% for dilution ratio greater than 2,000

Accuracy

less than 5% for dilution ratio smaller than 2,000

less than 10% for dilution ratio greater than 2,000

Calibration mode

Mass flow rate calibration

Soapbulb meter

Calibration check

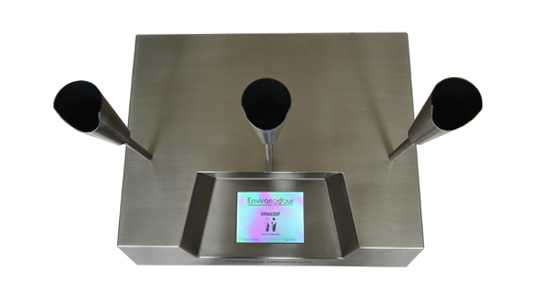

Sniffing cups

Three custom-designed cups

Flow rate at sniffing cups

20 litres per minute or user selectable

Required sample volume

2 litres if odour concentration (OC) > 100 OU/m3 10 litres if OC < 100 OU/m350 litres if OC < 10 OU/m3

Maximum rounds per sample

Three rounds

Time between dilutions

Less than 10 seconds

Calculation method

Odour concentration:

DynaScent method (student t-test method for the first two series)

Geometric means with retrospective screening (EN13725 method, GB14675)

Result presentations

Numerical and graphical representations

Data export

Excel or ASCII format.

Response input device

LCD touch screen

Average throughput

Three samples per hour with a panel of six assessors

External operating pressures

600 kPa for odour-free air (oil-free and dry air); 30 kPa for sample container

Wetted parts

Stainless steel 316 or FEP-Teflon designed with minimum wetted surface

Computer interface

Bluetooth 2.0 or above

Dimensions

W48 cm D40 cm T52 cm

Weight

22 kg

Power requirements

100 VAC - 230 VAC

Computer operating system

Windows7/Windows8/Windows10

Package

One unit DynaScent digital dynamic olfactometer and DynaScent software, two sample containers and operating manual

Accesssories:

Oil-free air compressor

Odour-free air filtration

DynaMeter calibration kit

QA/QC manual

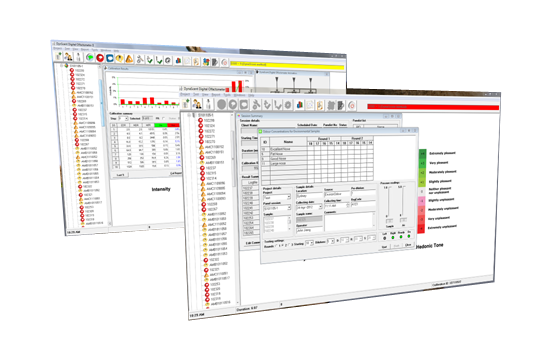

DynaScent Digital Olfactometer Graphic User Interface (GUI)

DynaScent Digital Olfactometer Graphic User Interface (GUI) LCD touch screen

LCD touch screen